Hyperspectral Mineralogy

Corescan’s hyperspectral scanners integrate high resolution reflectance spectroscopy, core photography and 3D laser profiling to map mineralogy, mineral composition, core morphology and geotechnical rock properties for use in exploration, resource modelling, ore processing and environmental remediation.

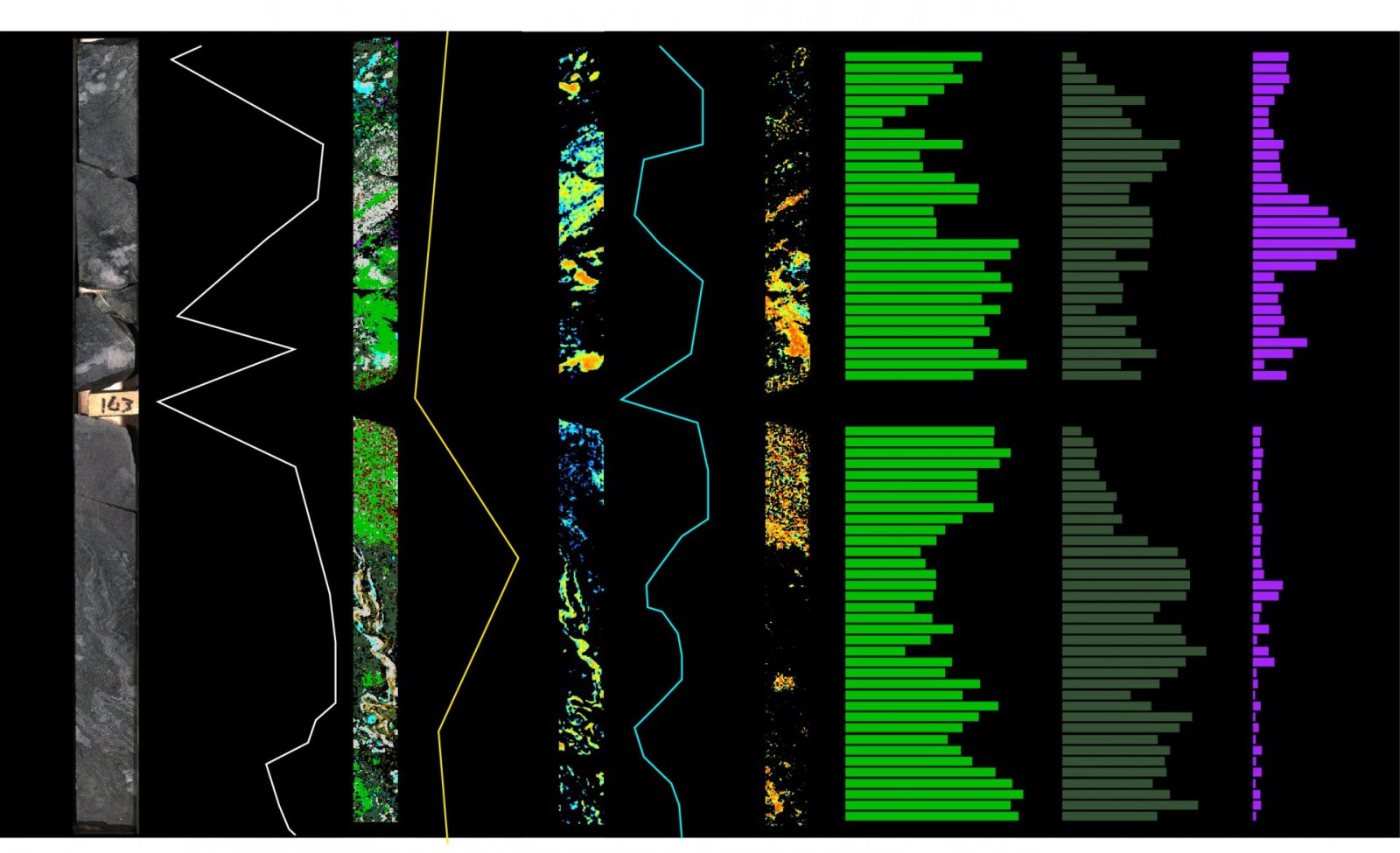

Corescan provides geologists, metallurgists and engineers with a rapid and reliable mineralogical profile of each drill hole, including image based mineral occurrence, mineral assemblage, mineral composition and geotechnical structure and rock property maps. Interval based quantitative logs are also produced at varying scales for integration with geological databases and 3d modelling software.

The foundation of the quality service provided by Corescan is our team of devoted spectral geologists that combined have over 150 years’ experience in spectral interpretation spanning all mineral deposit types and the petroleum industry. Corescan geologists welcome client interaction at all stages of the interpretation process.

The Corescan interpretation process is a mixture of expert geological knowledge, spectral interpretation expertise and automation that leads to accurate and precise data interpretation with fast turnaround times for delivery of image and point data products.

Unlike traditional spectral systems used in rock sampling (generally hand-held/lab-based commercial spectrometers used to measure single points along lengths of core at set distances), the fine spatial resolution and continuous imaging capacity of a HCI is able to capture a large number of pure pixels providing a comprehensive and easily determined group of end member minerals that are subsequently mapped throughout the borehole.

All mineral identification is conducted using Corescan’s in-house proprietary software.

Through an initial testing and consultation process, our spectral geologists create a site-specific library for each deposit or reservoir, often dividing this further into type-domain libraries for resource zones.

Such libraries are used throughout the mapping of the deposit or reservoir and provide a definitive record of project mineralogy.

After a library is established, spectral identification of minerals is automated using a matching algorithm set-up specifically for each mineral and project by the spectral geologist. This subsequent automation provides for fast turnaround times and delivery of mapping products in mature projects.

The imaging nature of the data means mineral spatial relationships (e.g. disseminated, veined, intra-fracture, etc.) are immediately apparent.

The high spectral resolution and signal to noise ratio (SNR) of an HCI system also allows for confident mapping of compositional parameters of individual alteration minerals present throughout a section of core.

- Variations of these parameters (such as degree of crystallinity, amount of aluminum, iron, magnesium etc.) may relate to pre- and syn-mineralisation phases which can be distinguished from those parameters relating to post-mineralisation events.

- Such parameters may also permit geoscientists to infer relative formation temperatures or information related to reservoir chemistry (in oil/gas and geothermal applications) and source fluids.

The calculated mineral map for a section of core (or cuttings) can be used to compute semi-quantitative down-hole mineralogy (semi-quantitative implies that the mineralogy mapped is limited to those minerals that are active in the VNIR-SWIR). This digital mineralogical “assay” data is easily exported for use in third party 3D visualisation software for mine or reservoir planning, as well as into logging software for comparison with traditional down-hole data (e.g. element assay, temperature, conductivity, etc.).

- The semi-quantitative nature of the data allows for rigorous statistical analysis of mineralogical data using third party software.

- While done in the past with traditionally logged data, the consistent mineralogical data from Corescan provides unbiased input data for such models.

- Ultimately this data can improve the accuracy and consistency of ore/resource projections for exploration, mineral process and metallurgical studies.

Both physical and mineralogical textures are also easily tracked with an HCI system. General texture such as degree of veining or dissemination can be identified using the hyperspectral-derived mineral maps. This differs greatly from historic methods that utilise simple photography and basic mineral colour; a method prone to high levels of error and subjectivity.

Physical texture, such as faults, fractures and RQD, are performed using the high-resolution laser profiler data. The combination of derived mineralogy with texture produces sophisticated new products with applications in the geotechnical and mineral process fields. Automated rock quality measurements by Corescan bring new efficiencies and accuracy to an important, but expensive and time-consuming process.